Start Automating with Cobots

Unlock the future of manufacturing with collaborative robots (cobots)! Designed to seamlessly work alongside your team, our cobots automate repetitive tasks, improve efficiency, and enhance precision without the need for complex reconfigurations.

Whether you're looking to optimize production lines, reduce costs, or increase safety, our cobots offer the perfect solution for modern manufacturing challenges. Let us help you revolutionize your processes and elevate your business to the next level.

Scroll down to check out some of the most important reasons to integrate cobots into your manufacturing process.

Why Cobots?

Increased Productivity

24/7 Operation: Cobots can work continuously without the need for breaks, shifts, or rest, leading to higher production output.

Fast Setup: They are often quicker to set up compared to traditional industrial robots, and can be easily reprogrammed for different tasks, improving efficiency.

Improved Worker Safety

Safe Collaboration: Cobots are designed to work alongside human operators without the need for safety barriers, using sensors and advanced programming to avoid collisions and ensure safety.

Reduced Risk of Injury: By taking on repetitive, heavy, or hazardous tasks, cobots reduce the risk of strain or injury for human workers.

Cost-Effective

Lower Initial Investment: Cobots typically cost less than traditional industrial robots, making automation more accessible for small and medium-sized businesses.

No Need for Extensive Infrastructure: They don't require costly safety systems, fences, or extensive floor space, and they can be integrated into existing production lines without massive changes.

Flexibility & Versatility

Easy Reconfiguration: Cobots can be easily reprogrammed or switched between tasks, making them ideal for environments that require frequent product changes or small-batch production.

Adaptability: Whether it's assembly, picking, packaging, or inspection, cobots can be adapted to many tasks, making them highly versatile.

Enhanced Quality & Consistency

Precision: Cobots can perform tasks with high accuracy and repeatability, reducing human error and ensuring consistent product quality.

Error Reduction: Since they follow programmed instructions precisely, they help eliminate mistakes that might occur in manual operations.

Ease of Use

Intuitive Programming: Many cobots have user-friendly interfaces and do not require deep technical expertise to program, enabling workers to set them up quickly.

Minimal Training: Operators generally need less specialized training compared to traditional robots, so businesses can get up and running faster.

Scalability

Easily Scalable: You can start with one cobot and add more as your production needs grow, making them ideal for scaling operations gradually without overwhelming the workforce or infrastructure.

Improved Worker Satisfaction

Focus on Higher-Value Tasks: Cobots take over the tedious and physically demanding tasks, allowing human workers to focus on more complex and rewarding work. This can improve job satisfaction and reduce turnover.

Small Footprint

Space-Efficient: Cobots are compact and can be easily integrated into spaces where traditional automation might not fit. This makes them suitable for smaller or more constrained production environments.

Collaborative Human-Robot Interaction

Human-Robot Partnership: Cobots are built to work with humans, not replace them. This creates a cooperative environment that improves overall workflow and leverages the strengths of both human workers and robots.

Did you know?

Most cobot projects can be completed under $50k. Contact us to get started!

Where can Cobots help?

|

- Spray Lubrication |

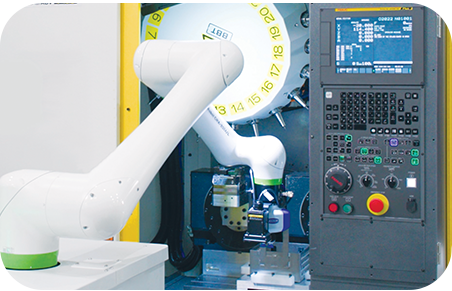

- Machine Tending |

|

- Pick 'n Place |

- Visual Inspection |

|

- Part Extraction |

- Ladling |

|

- Air Blasting |

- Quenching |

Reduce Risk with ROBOGUIDE

We are pleased to offer ROBOGUIDE, the programming robot simulation software for FANUC robots. ROBOGUIDE allows users to create, program and simulate a robotic workcell in 3D without the physical need and expense of a prototype workcell setup. With virtual robots and workcell models, ROBOGUIDE reduces risk by enabling visualization of single and multi-robot workcell layouts before actual installation.

Interested in working together?

to exceed your expectations.